In the second effectiveness study, three different speeds (50, 100, and 130 km/h) with two different decelerations (3.0 and 6.0 m/s 2) with an initial temperature of less than 80☌ were considered. In the first effectiveness study, two different speeds (50 and 100 km/h) with two different decelerations (3.0 and 6.0 m/s 2) with an initial temperature of 80☌ were considered.

Three effectiveness studies were performed. The establishment of 90% contact between the pad and disc was done by a bedding test at a 50 km/h speed with 3.0 m/s 2 deceleration with 200 applications having an initial brake temperature of 100☌. If the error was more than 8%, then a third sample was tested. For consistency in results, two samples were tested. The calibration of the data acquisition system used to record the data was done through process variable equipment, namely pressure sensors, temperature sensors, speed sensors (encoders), and torque measurement (load cell) as per the National Traceability Standards of NABL-certified laboratories. The parameters were an inertia of 50 kg ms 2, a rolling radius of 0.293 m, an effective radius of 0.103 m, a pad thickness with a backplate of 15.1 mm, and a mating surface of cast iron. The fade, recovery, and effectiveness characteristics of the developed brake pads were analyzed using a full-scale inertia brake dynamometer as per the JASO C-406 schedule. A quick assessment of the tribological characteristics was done using the Chase test following IS 2742 Part 4 for a brake pad sample size of 625 mm 2 that was made to slide against a 280 mm diameter cast iron drum.

To check the consistency, three samples were tested and the average values reported.

It was carried out according to JIS D 4418. After the required time, the heater was switched off, and the cooling of the samples was performed at room temperature. Porosity was found by placing brake pad samples of 625 mm 2 in a desiccator for 24 h and then soaking it in a preheated SAE 90-grade oil bath at 90☌ ± 1☌ for 8 h. The image analysis technique used by industries was followed to find the adhesion.

Definition archimedes principle iso#

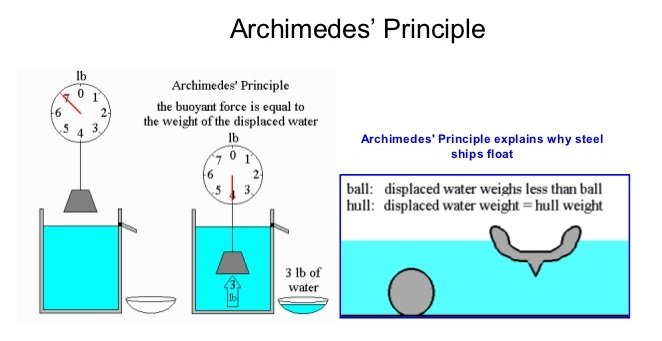

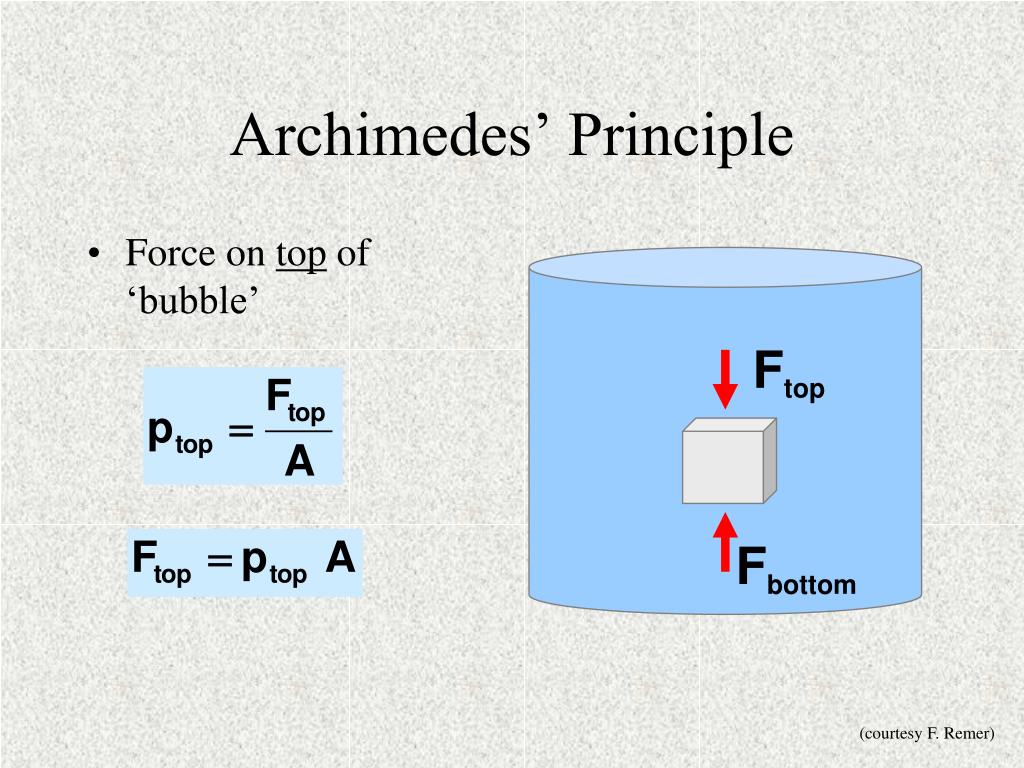

The above shear tests were performed as per ISO 6312. The hot shear strength was measured by heating the pad to 200☌ and maintaining at that temperature for 30 min while cold shear strength was found by testing the brake pads under ambient conditions. The above tests were performed as per IS2742 Part 3. For both tests, the difference in thickness was noted. The brake pad samples were cut to a 50 mm × 25 mm size and immersed in water in ambient conditions for 30 min. The pad swell on heating was found by considering a sample of size of 10 mm × 10 mm × 4 mm that was maintained in a hot air oven for 40 min at 200 ± 3☌. The difference in mass loss was noted and reported. The mass loss due to the ignition of the brake pads was found by considering 5–10 g of the developed sample in a silica crucible heated to 800☌ and maintained at that temperature for 2 h in a muffle furnace. Uncured resins were found using the acetone extraction test by using a Soxhlet extraction apparatus. Resins that were not appropriately cured were found using the Soxhlet extraction apparatus by acetone extraction. The hardness was measured by Rockwell hardness using the K scale (steel ball indenter with ϕ 3.125 with 1500 N load). Lenin Singaravelu, in Tribology of Polymer Composites, 2021 2.3 Characterization of the developed brake friction compositesĪ density apparatus that uses the Archimedes principle was used to find the density.

0 kommentar(er)

0 kommentar(er)